Overview – Making Complex Parts with Extreme Accuracy

Modern industries need multi-axis machining to create high-precision parts that are both strong and complex. Traditional machining can only move in three directions—up and down, side to side, and front to back. But many industries, like aerospace and automotive, need parts with more detail and tighter tolerances.

Multi-axis machining lets machines move and rotate in several directions at once. This helps make detailed parts in a single step, which improves accuracy, speed, and efficiency.

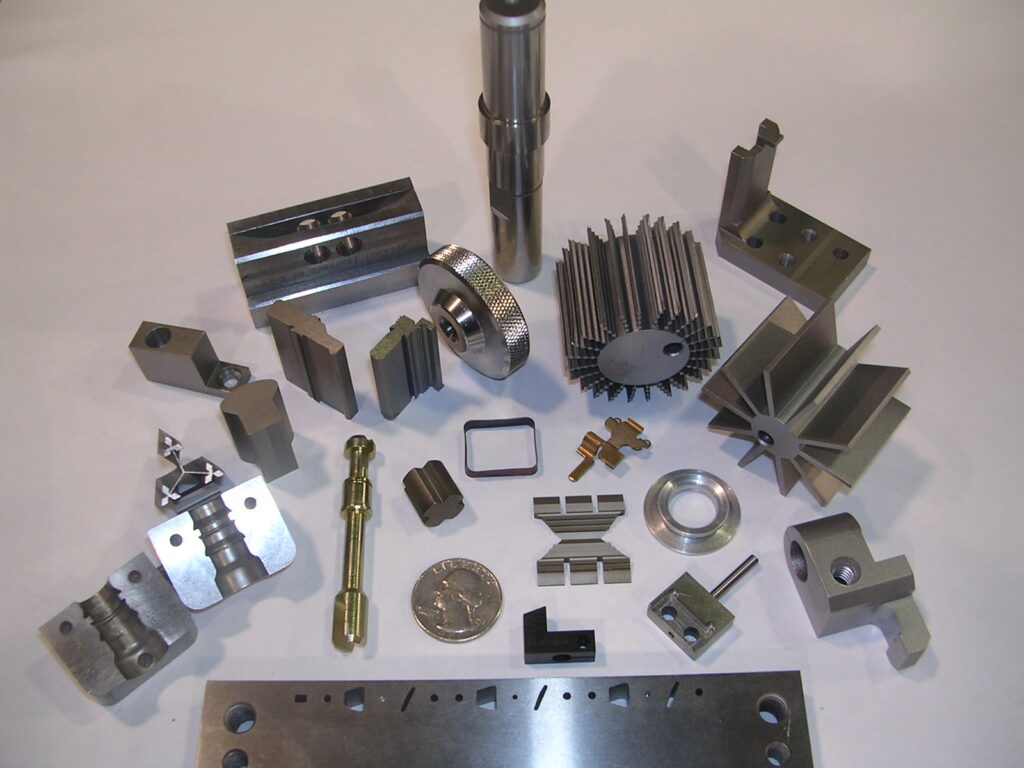

At Krukemeier Machine & Tool, we focus on 2, 3, 4, 5, and 9-axis machining. This allows us to work with both simple and extremely complex parts. We also offer wire EDM, CNC milling, CNC turning, and precision grinding.

Our skilled team and modern facility make sure every part meets top industry standards. This includes AS9100 and NADCAP certifications.

If you need custom prototypes, aerospace parts, or high-performance car parts, we have the tools and skills to help.

What is Multi-Axis Machining?

Multi-axis machining is a method that allows machines to move and cut parts from multiple angles. Traditional machining only moves along three axes:

-

- X-axis (left to right)

-

- Y-axis (front to back)

-

- Z-axis (up and down)

Multi-axis machines add rotational movement, allowing the tool to tilt and turn in different directions. At Krukemeier, we use:

-

- 2, 3, 4, 5, and 9-axis machining to create detailed, high-precision parts.

-

- Wire EDM and Ram EDM for extremely fine cuts.

-

- CNC milling and turning to shape strong materials like titanium, aluminum, and hardened steel.

This advanced technology reduces setup time, improves accuracy, and allows us to make complex parts faster.

Benefits of Multi-Axis Machining

Many industries use multi-axis machining. It creates better-quality parts with less waste and speeds up production times. Here’s why:

-

- Better precision – Occurs because operators don’t have to move parts between machines, which reduces the chance for mistakes. We achieve ±0.0005” tolerances, making our parts extremely accurate.

-

- More Complex Shapes – creates deep cuts, curves, and intricate designs that other methods can’t.

-

- Faster Production – Because we can machine parts in one continuous process, we save time and lower costs.

-

- Setup- Fewer setups lead to less material waste, keeping costs low.

-

- Materials – Our machines work with many materials. They can handle lightweight aluminum and strong titanium. They can also work with special alloys used in aerospace and medical fields.

Krukemeier delivers high-quality parts faster and more efficiently than traditional machining.

Why Krukemeier is the Best Choice for Multi-Axis Machining

Not all machining shops have the same level of experience or equipment. Krukemeier Machine & Tool stands out because we offer:

-

- A High-Tech Facility – Our 15,500-square-foot shop has the newest multi-axis machines for all kinds of projects.

-

- Extreme Accuracy – We achieve ±0.0005” tolerances for industries where precision is critical.

-

- Complete Machining Services – We offer wire EDM, CNC milling, CNC turning, and precision grinding.

-

- Industry Certifications – We are AS9100 and ISO 9001:2015 certified, NADCAP approved, and a trusted Lockheed Martin vendor.

With these capabilities, we deliver high-quality parts faster, at lower costs, and with extreme precision.

Industries That Depend on Multi-Axis Machining

Many industries need strong, high-precision parts that only multi-axis machining can produce.

Aerospace & Defense

-

- Examples: Turbine blades, landing gear, and structural supports.

-

- Why it matters: These parts need to be lightweight, strong, and incredibly precise.

Automotive & Motorsports

-

- Examples: Engine parts, transmission components, and custom performance parts.

-

- Why it matters: ensures smooth performance and durability.

Medical & Industrial Manufacturing

-

- Examples: Surgical tools, medical implants, and industrial machinery components.

-

- Why it matters: Medical devices require extreme accuracy for safety and reliability.

Krukemeier works with all these industries, creating parts that meet the highest quality standards.

How Multi-Axis Machining Improves Efficiency

Multi-axis machining is more efficient and cost-effective, making better parts that speeds up manufacturing.

-

- Fewer Setups – Since we can cut parts from multiple angles at once, we avoid moving them between machines.

-

- Faster Production – Less downtime means shorter lead times and quicker deliveries.

-

- Less Waste – With fewer errors and better planning, we use less material and cut costs.

-

- Scalable for Any Job – Whether you need a single prototype or a full production run, we can handle it.

At Krukemeier, our multi-axis machining services help customers get high-quality parts faster and at a better price.

Krukemeier – The Leader in Multi-Axis Machining

At Krukemeier Machine & Tool, we are experts in multi-axis machining, wire EDM, and CNC milling. Our advanced technology allows us to make high-performance parts with the highest accuracy.

We work with aerospace, automotive, medical, and industrial companies to produce precision-engineered parts that meet the toughest standards. We can help you with a single prototype or a large production run. We have the experience, technology, and certifications to deliver what you need.

Looking for precision machining?