Manufacturing is evolving fast. Artificial intelligence (AI) now powers computer-aided design (CAD) systems. These AI-powered tools help engineers design parts that are easier to make, with fewer mistakes and faster turnaround. Instead of designing in a vacuum, AI gives instant feedback based on real-world machining limits.

For precision shops like Krukemeier Machine & Tool, this is a game-changer. Better designs mean fewer changes, smoother production, and happier customers. Especially in industries where getting it right the first time matters the most.

Smarter Product Designs with AI-Powered CAD Software

Can AI in CAD reduce the need for revisions? Yes, and that’s one of the strongest advantages.

Creating a part that works in theory is not the same as producing one that works in practice. Traditional CAD tools allow engineers flexibility. Many designs end up too complex, too fragile, or simply not cost-effective. These limitations often lead to delays or rework on the shop floor.

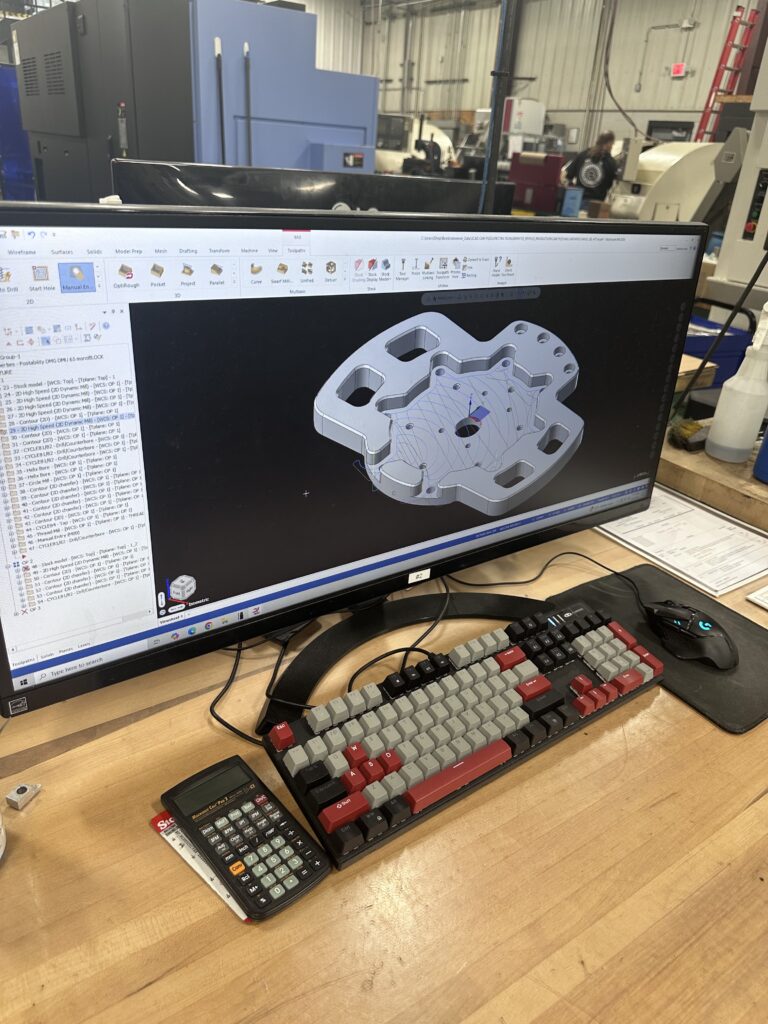

AI-powered CAD software addresses this by offering real-time feedback during the design phase. These advanced tools, often driven by machine learning and trained in design, can analyze geometry, materials, and tolerances. They suggest adjustments that enhance product manufacturability, reduce complexity, and improve outcomes.

In shops like Krukemeier’s, which serve industries like aerospace and medical, small design changes make a big difference. Adjusting a radius or choosing a better material can improve how a part performs and reduce machining time. This not only enhances product quality but also improves cycle times and reduces scrap.

Reducing Repetitive Tasks and Revisions through AI Technologies

Design revisions are a constant pain point in manufacturing. Often, engineers spend time adjusting parts after discovering they don’t meet machining constraints. These back-and-forths waste time and increase labor costs. But AI technologies are helping eliminate that issue by reducing repetitive tasks and predicting failure points early in the design phase.

AI models built into CAD systems can recall previous designs and outcomes, enabling predictive suggestions to avoid known errors. If a certain pocket depth or thread size has caused issues in the past, the software flags it automatically.

In a shop like Krukemeier’s, this leads to faster quotes and fewer test runs. It also helps teams make better choices for setup and fixturing. With lead times of 16–18 weeks, cutting revisions saves time and money. It also helps make better use of machines and people

Plus, as more manufacturers shift toward the principles of Industry 4.0—where data and connectivity drive decisions—these AI systems become even more essential for competitive edge.

Speeding Up Manufacturing Operations with AI and Predictive Maintenance

When it’s time to move from design to production, AI continues to deliver value. Beyond CAD, AI is enhancing manufacturing operations through intelligent toolpath generation, workflow automation, and even predictive maintenance.

Modern AI systems can automatically generate toolpaths based on CAD models, ensuring efficient cuts and reducing unnecessary tool changes. The system optimizes these toolpaths for speed, tool wear, surface finish, and stability. These efficiencies help Krukemeier’s multi-axis machines and EDM systems run longer. In some cases, they even support lights-out production.

Predictive maintenance is another benefit of AI in manufacturing. By analyzing spindle load, vibration, and thermal data, AI tools can forecast equipment wear before failure occurs. This avoids unexpected downtime and protects the tight delivery schedules customers depend on.

Ultimately, AI doesn’t replace skilled machinists—it amplifies their capabilities. It frees them from repetitive tasks and allows them to focus on critical thinking and quality control. In the right hands, AI-enhanced CAD and automation tools become force multipliers.

Why AI in CAD Design Is Transforming Manufacturing Industries

AI-powered CAD software is not just changing how parts are drawn—it’s changing how they are made. By enhancing product designs, reducing rework, and enabling smarter manufacturing operations, these technologies bring clarity, speed, and intelligence to a complex process.

For manufacturers like Krukemeier Machine & Tool, using AI in product development makes sense. It helps save money, improve quality, and speed up production. These gains are key for industries like defense and medical, where reliability matters.

As Industry 4.0 grows, shops that use AI will lead the way and stay ahead. That’s how manufacturing stays smart, flexible, and ready for what’s next.

Need a quote or want to review your design with our team? [Contact us here].